UNIPADEL is The Biggest Padel Court System Manufacturer and Exporter in the South of China. With sophisticated technology and high-end materials, UNIPADEL provides a complete set of solutions, meeting needs of flooring, lighting, and structure. With all CE certificated Tempered Glass, Artificial Grass, Columns, Frames, Lighting System, UNIPADEL Perfectly observe the standards of EU quality.

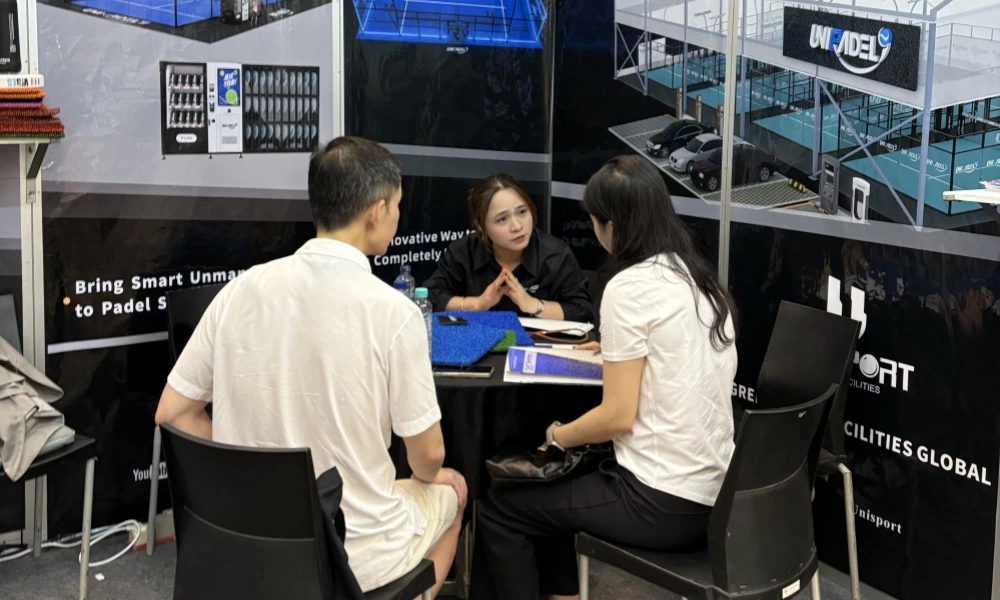

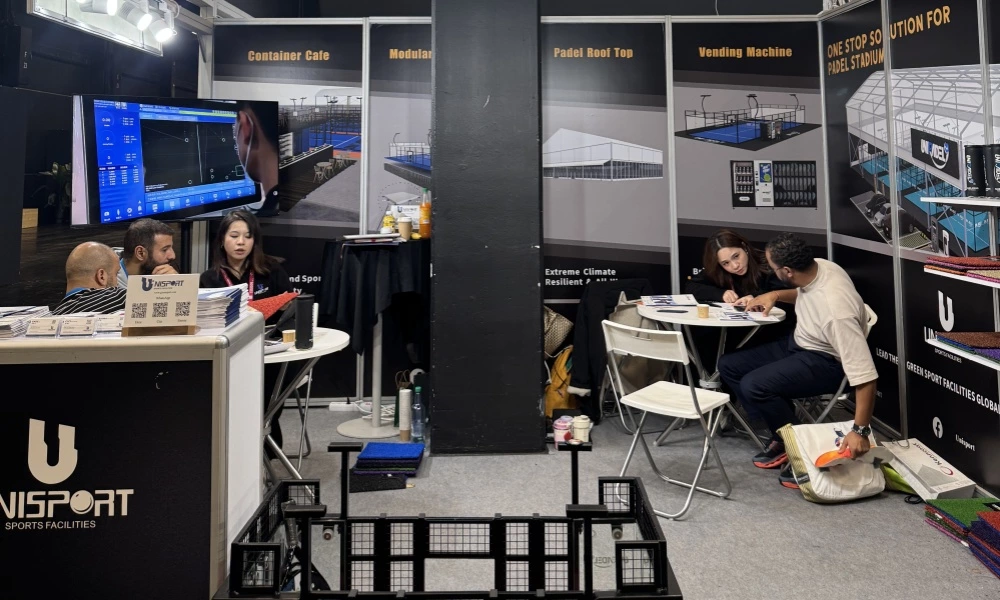

UNIPADEL owns various ranging, from Economical level to Competition level that is international standards, aiming to assist customers all over the world to build their dream courts with flexible customization service. In addition, we provide a complete service process from site planning and assessment, custom design, manufacturing and production, and installation and after-sales service. We also provide our customers with additional supporting services such as vending machines, custom balls and rackets, and custom container shops for club use.

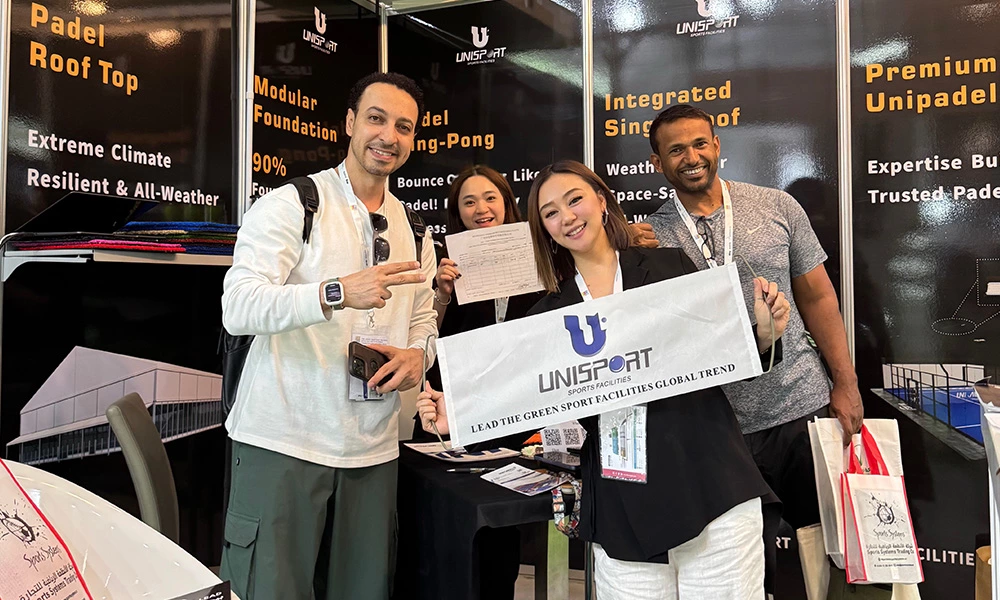

UNIPADEL is dedicated to developing advanced, safe, and environmentally friendly padel court structures. To date, UNIPADEL has established reliable, long-term partnerships with clients primarily from Southeast Asia, South America, Europe, the United States, Australia, Saudi Arabia, and the United Arab Emirates. In the future, UNIPADEL will continue to refine its high-end craftsmanship and looks forward to establishing business relationships with key partners from around the world to create shared value.

UNIPADE Aiming to Provide our customers refined quality and reciprocal competitive price by our Comprehensive Sports Facilities. UNIPADEL , Lead the Global Green Sport Facility Trend.

Factory Area

Exported countries

Factory Employee

Cooperative Client

UNIPADEL's padel court structure utilizes high-strength Q235 hot-dip galvanized steel, specifically designed for outdoor sports environments. It meets international standards for mechanical properties and composition, ensuring durability and long-term stability. High-strength galvanized steel is also used in key areas for enhanced corrosion resistance.

Black carbon steel is welded, polished, hot-dip galvanized, and polished again. Finally, they are sprayed with a weather-resistant protective layer over 100 microns to ensure long-term corrosion resistance and aesthetic appeal.

Galvanized pipes and hot-dip galvanized steel wire are welded together, polished, shot-blasted, and then coated with an epoxy primer and low-temperature baked. Finally, they are powder-coated twice for dual protection and long-lasting durability.

electrostatically sprayed with zinc-based powder and then epoxy powder coated to effectively protect against UV rays, corrosion, and mechanical impact. The construction utilizes an integrated screw system, with all nuts and bolts made of 304 stainless steel, ensuring a secure and durable connection.

Leave your contact information and let us give you a quotation

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.